Replenishing Cost

How Much Does It Cost You To Buy?

In a previous blog article entitled, “The Mysterious Cost of Carrying Inventory,” we published a questionnaire that you can fill out, return to us, and have us calculate your specific company’s inventory carrying cost percentage. That is, what it costs to maintain a dollar’s worth of stocked inventory in your warehouse for an entire year. The carrying cost is used in many inventory analysis and planning formulas including the economic order quantity formula; the calculation that is designed to determine your “best buy” replenishment quantity.

We published the questionnaire in response to many inventory consultants and “gurus” contention that it is too difficult to accurately calculate your company’s inventory carrying cost and that a “rule of thumb” (e.g. the prime rate plus 20%) or default value (e.g. 25% – 35%) should be used in all formulas requiring a carrying cost percentage. Based on your responses on the completed questionnaires, and the resulting carrying cost percentages, we have concluded that:

- It is fairly easy to calculate a distributor’s or manufacturer’s inventory carrying cost

- There is no single accurate default value for the inventory carrying cost

The Effect of Carrying Costs

How much of an effect does the carrying cost percentage have on calculated replenishment quantities? Well, using a 25% carrying cost in the EOQ formula results in 20% greater replenishment quantities than a 35% carrying cost. Just think of what 20% more inventory would cost your company. Remember that the EOQ is supposed to be the quantity that provides you with the lowest total cost. Replenishing inventory with quantities other than this “best buy” quantity will cause your company to experience higher costs and/or excess inventory.

There is no way to determine which order quantity represents the “best buy” without accurately calculating your company’s specific carrying cost percentage and cost of ordering stock. The cost of ordering stock is the cost of issuing and processing a line item on replenishment order. I have read many articles stating, as with the inventory carrying cost, that this number is also too hard to calculate. Many analysts suggest that you should just pick a value between $5.00 and $6.00. As with using rules of thumb for the inventory carrying cost, if you just guess at your company’s cost of ordering stock, the resulting economic order quantity will not represent your company’s best buy quantity. In fact utilizing “rules of thumb” for the carrying cost percentage and cost of ordering stock results in an economic order quantity formula that probably won’t maximize your company’s profits.

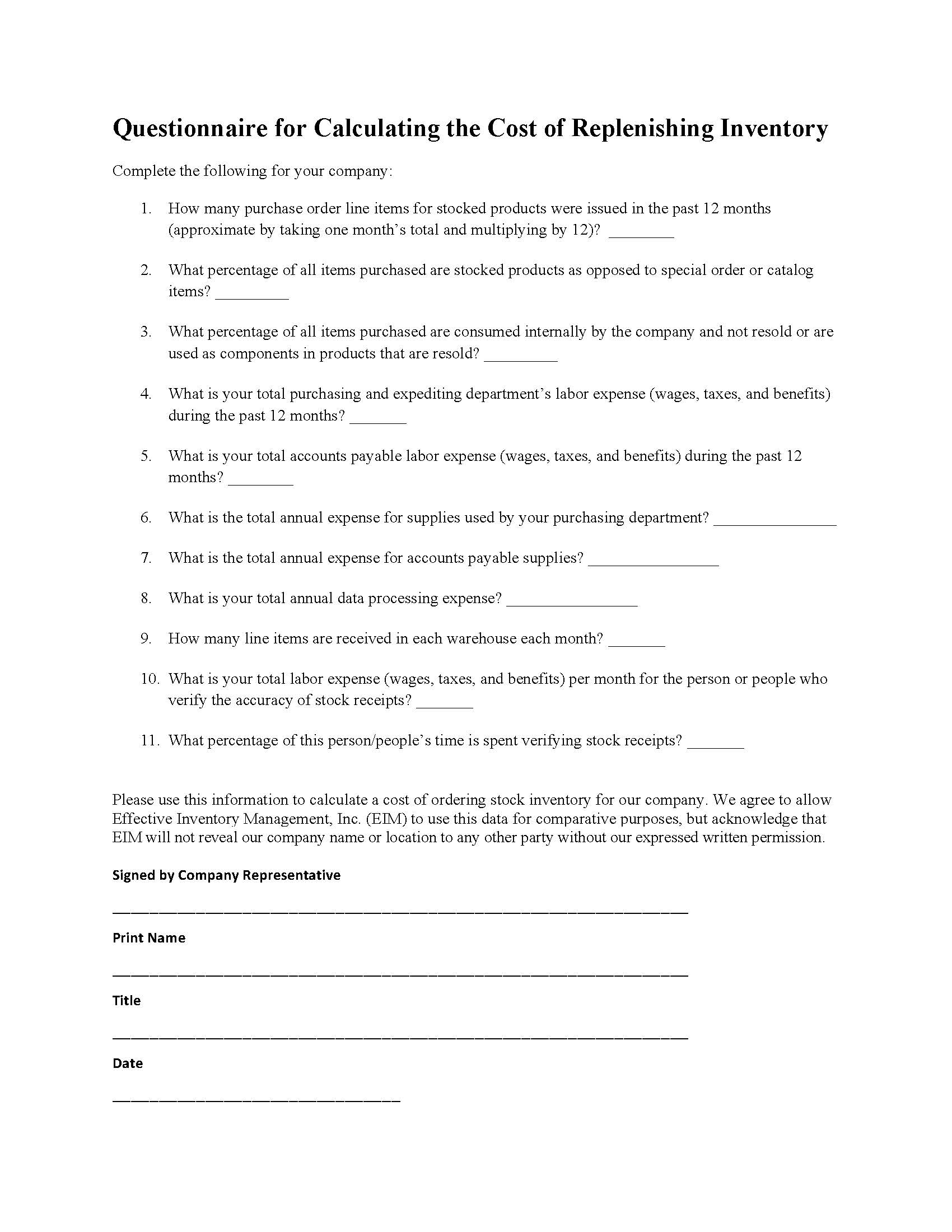

So this month we publish a questionnaire that allows us to calculate your company’s cost of ordering a line item of stock material. As with the carrying cost questionnaire, if you will answer these questions and send your responses to us by email, mail or fax, we will calculate your cost of ordering stock and send you the results. If we have relevant data in our files, we’ll include a comparison of your answers to each question to others in your region and industry. There is no charge for this service as long as you agree to let us add your information to our database. Please note that all responses are confidential. Data we present to other companies will not identify your company name or location.

Click the image below to open and print the PDF document.

Please send completed questionnaires to:

Email: [email protected]

Effective Inventory Management, Inc.

106 N. Denton Tap Road – Suite 210-127

Coppell, TX USA 75019

Phone (972) 304-3325

Fax (972) 393-1310

© 2014-2017. Effective Inventory Management, Inc. All rights reserved. This article cannot be reprinted, or reproduced, in whole or in part, without the expressed written permission of Effective Inventory Management, Inc.