If one of your warehouse employees walks past an item lying in the middle of a warehouse aisle, or out of place on a shelf, do they pick it up and put it in its proper location? Do they pretend not to see it? Do they feel they are too busy to deal with it? Do they kick it out of the way?

The answer to this question provides a good indication of what your employees think about your inventory. For any company to be successful, its employees must see the direct relationship between inventory and their paycheck. The same “pile” of money that is used to pay employees is used to buy inventory. Furthermore, inventory must be transformed back into cash (through sales) for the company to have the money to pay its employees in the future. You cannot be successful (or perhaps even survive) unless all your employees understand this relationship.

Like any other expense, material losses must be paid for with gross profit dollars. If a company’s average gross margin is 25% (a respectable number for many distributors), the organization earns a 25 cent gross profit for every dollar of sales. The replacement material along with all of your other expenses has to be paid for with these 25 cents on the dollar.

The value of lost material includes any inventory that your company purchases that cannot be sold to a customer or used to produce other goods or services that will be sold to a customer. For example:

- Missing or stolen inventory

- Broken or damaged stock

- Obsolete products (less any liquidation value)

- Remnants of an item that are too small to be sold or used (also known as “orphan inventory” or “drops”)

- Quantities of non-stock products ordered for a specific customer that exceed what the customer actually buys

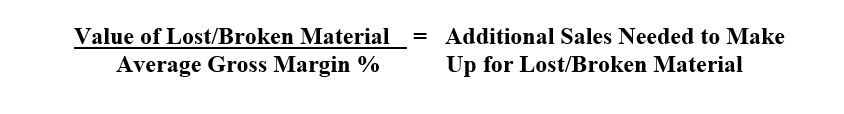

You can calculate the additional sales you must generate to make up for “lost” material with the equation:

If you divide the value of the lost material by your company’s average gross margin percentage, you determine the

And this equation doesn’t consider the other costs you incur when inventory is lost:

- Additional expenses incurred processing emergency shipments and “fighting fires”

- Labor wasted searching for missing material in the warehouse

- Disappointing customers by promising material that exists in the computer system but can’t be found

Every week post the amount of lost and damaged material and the additional sales you need to generate to make up for that loss. Let every employee see and appreciate the true cost of bad inventory control!