Today, many firms are trying to concentrate on the “core competences.” They want to outsource minor tasks and activities when it is cost effective to do so. For a distributor, an example of one of these tasks is the replenishment of less-expensive products. For a manufacturer, it may be the procurement of MRO (maintenance, repairs, and operations) inventory. A popular way to outsource these procurement activities is a vendor-managed inventory (VMI) agreement. Under a VMI agreement, a supplier takes full responsibility for maintaining stock of its products at a customer’s facility. VMI agreements differ from traditional consignment agreements in that the customer is billed for material when it is delivered, not when it is consumed or issued. When establishing a VMI agreement, the supplier and customer must agree on:

- The specific products that will be covered under the VMI agreement.

- “Acceptable availability” of these products at the customer’s site and the corresponding investment required by the customer. Usually the supplier and customer will agree on a “service level,” which is the percentage of orders for a product that can be completely filled out of the VMI stock inventory. The higher the agreed-upon service level, the more the customer will have to invest in the supplier’s products.

- How often the stock of these products will be replenished.

- The automatic return of material that is no longer needed by the customer.

Potential advantages for a customer participating in a VMI program include:

- Eliminating the cost of managing replenishment parameters and issuing purchase orders.

- Establishing an extremely reliable source of supply for products that are very important to its operations but represent a relatively small investment.

Advantages to the supplier include:

- Securing all of a customer’s business for the types of products it supplies.

- The ability to better plan its own inventory replenishment needs because the supplier’s buyers can monitor the actual sales or use of its products at the customer’s site.

But there are also risks to participating in a VMI program. For a supplier, the largest risk is the high administrative cost. After all, it is assuming responsibility for a considerable amount of replenishment activity that was previously carried out by the customer’s buyers. Gross profits earned from sales to the customer have to be large enough to cover these additional expenses. The customer’s risks include:

- Reliance on a single source of supply. Will the supplier be able to meet its commitments of product availability?

- Cost control. Will the outsourcing of these replenishment activities actually result in lower overall costs for the company?

- Possible exposure of confidential information. In order to properly replenish a customers inventory, the supplier must have access to past usage data, projections of changes in the future demand of products, and other proprietary information.

These concerns can be overcome with a properly structured VMI program. A VMI implementation should include:

A way for the supplier to monitor the status of inventory at the customer site. This is often accomplished by sending electronic data interchange (EDI) transactions between the supplier’s and customer’s computer systems. Automated dispensers (similar to vending machines) are also utilized to record material consumption.

In order to determine when products should be replenished as well as the quantity that is needed, the supplier must have current information as to how much of each product is being consumed at the customer site, when stock receipts arrive, and other transactions that affect on-hand quantities.

The recalculation of replenishment parameters for each item at least once a month.

These replenishment parameters include:

- For items with recurring usage: These are products that are sold or used on a regular basis. For each of these products, the supplier must calculate the anticipated demand of each product between deliveries along with a safety-stock quantity. The safety stock is reserve inventory maintained in case actual usage exceeds anticipated demand. Larger safety-stock quantities require a greater investment by the customer, but will help avoid stockouts of products whose actual usage is hard to predict. Good replenishment software can show the customer different inventory investments and the resulting service level – that is, a realistic estimate of the percentages of requests that can be completely filled from stock inventory. Here is some data from a recent VMI implementation with 838 items with recurring usage:

| Safety Stock | Safety Stock Investment |

Average Inventory Investment |

Service Level |

| 1-Week Supply | $48,288 | $80,377 | 95.7% |

| 2-Week Supply | $96,577 | $128,666 | 97.7% |

| 3-Week Supply | $144,865 | $176,954 | 98.8% |

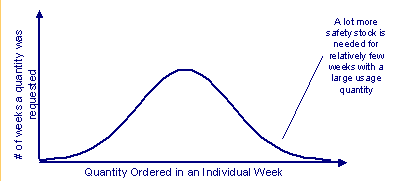

The average inventory investment is the sum of the safety-stock investment along with the average value of inventory that will be on hand between deliveries from the vendor. Notice that a much greater investment is needed to increase the service level by a small percentage. This is due to the fact that weekly usage of most items with recurring usage will follow a “bell curve”:

- For items with sporadic usage: These products are used infrequently, and are typically maintained based on a multiple of the number of normal order quantities that should be able to be filled from stock inventory. The normal order quantity is the number of pieces typically sold or used at one time. For example, if the item is sold by the dozen, the normal order quantity would be 12 pieces, Typically, one normal order quantity will be maintained for each of these items, but two normal order quantities may be maintained for very critical parts. Again, this depends on the amount of money the customer is willing to invest in this type of inventory.

The normal time period between deliveries to the customer. Most VMI agreements require the supplier to replenish stock at a customer’s site once or twice a week. Frequent replenishment helps to ensure that service level goals can be achieved.

A method of transmitting collaborative forecast information to the supplier. Collaborative information is normally gathered from customers, salespeople, and other sources and reflects anticipated changes in future usage of products. Note that it is common practice for the customer to assume full responsibility for additional inventory delivered due to collaborative forecasts – that is, there is a handling charge if this speculative inventory must be returned.

The automatic return of material that has not been used for “x” number of months. Remember that under a VMI agreement a customer has purchased stock on the advice of the supplier. If that inventory is not used within six to nine months after delivery (and is not designated to be a critical repair part), the supplier should automatically issue a return-goods authorization and give the customer full credit for the return.

Guarantees of performance. When it enters a VMI agreement, a customer invests in a specific amount of inventory anticipating a forecasted service level for the products supplied under the agreement. But what happens if this service level is not achieved? For example:

- The supplier may not retain enough inventory to adequately replenish the customer’s stock.

- The supplier may not replenish inventory as promised.

- The supplier’s forecasting and replenishment system may not result in the agreed-upon service level.

There must be penalties associated with non-performance. After all, the customer is putting its reputation in the hands of the supplier. However, as long as the supplier fulfills all of its commitments under the VMI program, the customer should commit to purchase all products on the VMI agreement from the supplier.

A well-structured VMI agreement has the potential to provide benefits for both the supplier and customer. If each partner concentrates on its core competences, both firms can increase their productivity and profitability.