Achieving Effective Inventory Management

“Effective inventory management enables an organization to meet or exceed customers’ expectations of product availability with the amount of each item that will maximize net profits or minimize its total inventory investment.”

Both effective inventory management and inventory control are essential in order to achieve the goal of effective inventory management. What is the difference between inventory control and inventory management?

- Inventory Management – Replenishing stock inventory with the right quantity, of the right item, in the right location, at the right time. Managing your inventory investment to maximize your net profits, or minimizing your inventory investment, while maintaining customer service goals.

- Inventory Control – Protecting the inventory you’ve purchased and stored in your facility and minimizing the cost of filling orders. That is controlling what you already own.

Effective Inventory Management, Inc. (EIM) is dedicated to helping distributors, manufacturers, retailers, and service organizations throughout the world achieve the goal of effective inventory management. EIM products and services include:

- Inventory Management and Inventory Control Workshops

- Books and Spreadsheet Sets that will help lead your organization to achieve Effective Inventory Management

- Consulting services that are customized to your needs and the inventory-related challenges you face.

Inventory Management Consulting Services

We will develop recommendations and customized tools that address your organization’s specific inventory challenges. The result will be an action plan that we will together execute to maximize the productivity and profitability of your inventory investment. This action plan may include:

- Changes to your current inventory-related policies and procedures.

- Analysis of how you use your current software.

- Development of customized spreadsheet tools.

- Suggestions of additional software that will address specific situations.

We begin by analyzing inventory data from your computer (ERP) system. In developing this analysis, we will:

- Identify possible dead stock and excess inventory

- Identify the products that probably should be stocked in each location.

- Highlight possible unusual activity in your sales or usage history.

- Determine the accuracy of your forecasts of future demand of products.

- From EIM’s library of forecast formulas, select the most accurate forecasting method (based on historical usage) for each item.

- Determine the best way to incorporate and evaluate market conditions and collaborative information from customers and salespeople into the forecast.

- Suggested replenishment parameters for each item.

- Calculate safety stock quantities required to achieve a certain level of service.

- Include a customized spreadsheet that can be utilized to upload the calculated replenishment parameters into your current computer software.

- Suggest a normal replenishment source for each item (i.e., vendor or transfer from another company location).

- Compare your current versus potential inventory investment and turnover.

- Project purchases and budgeted inventory amounts for each of the upcoming 12 months

- Provide inventory ranking by activity, profitability, and cost of goods sold.

- Suggested quantity of each product to be stored in a primary storage location.

- Determine the maximum and average on-hand quantity of each product that would need to be stocked in a surplus storage location.

Complete documentation is provided, as well as step-by-step instructions that allow you to produce the same analysis as often as you like in the future with updated inventory and sales data.

The actual analysis provided for a particular organization is dependent on factors such as:

- Industry

- Market Conditions

- Number of Stocking Locations (i.e., warehouses or branches)

- Number of Products Stocked in Each Location

- Profitability Objectives

Inventory Control Consulting Services

The goal of effective inventory control and warehouse management include:

- Store products to minimize the cost of filling orders

- Maintain accurate on-hand quantities

- Protect inventory from breakage, loss, spoilage, and theft

- Meet customer delivery expectations

- Operate a safe work environment

We begin the process of helping you achieve effective inventory control by looking at your current environment and situation. This review includes a detailed analysis of your material handling operations.

- Your basic rules for warehouse operations.

- A review of how you process every type of material-related transaction.

- Analyzing how products are stored in your warehouse.

- Determining if your warehouse space can be better utilized.

- Ensuring that your current storage units are appropriate for the material maintained in your facilities.

- Making sure you are using appropriate equipment and software? Can technology provide a cost-effective solution for lowering costs and reducing errors?

- How to ensure that inventory counts remain accurate.

- Ensuring that you have the right person in the right job.

- Creating comprehensive material handling policies and procedures manual.

- Helping you design and operate a safe working environment.

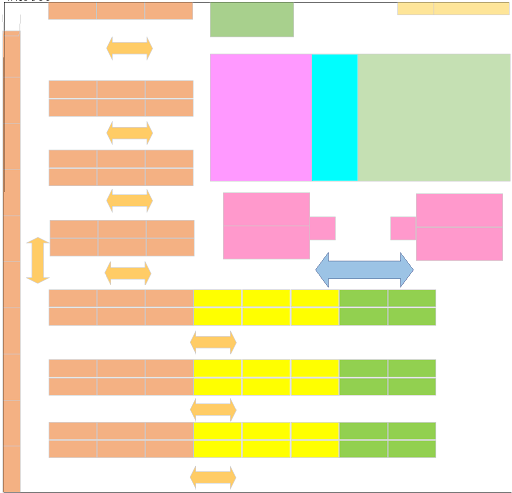

Here is a sample warehouse layout diagram (not to scale):

As with our inventory management consulting services, all of our inventory control projects include a year of phone/email/web-based support as we help you achieve effective inventory control.