Inventory Control and Material-Handling Services

The complete review begins with a detailed on-site analysis of your material-handling operations:

- Review of how you process every type of material-related transaction.

- Analysis of how products are stored in your warehouse(s), parts room(s) stores and other facilities. We will determine if your warehouse space can be better utilized.

- Verification that your current storage units are appropriate for the material maintained in your facilities.

- Verification that you are using appropriate equipment and software.

- Evaluation if additional or updated technology can provide cost-effective solutions for lowering costs and reducing errors.

- Evaluation of the accuracy of your current on-hand quantities.

- Determination if you have the right person in the right job.

- Evaluation if you have a safe working environment.

We then develop a report of recommendations and action plan. As with all our consulting engagements, we customize the process to meet your specific needs and circumstances. Typical plans include:

- “Material-Handling Policy and Procedure Guide” with detailed instructions for performing each material-handling operation.

- Training materials for warehouse employees.

- Detailed job descriptions and qualifications for each position.

- Suggestions for more efficient material-handling storage units and equipment.

- Layouts detailing bin locations, where each item should be stored, as well as shipping, receiving, and staging areas.

- Easy to understand metrics to measure warehouse performance.

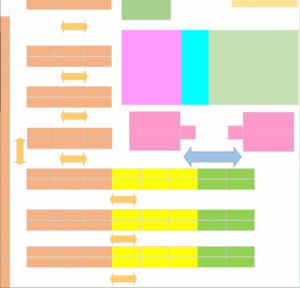

Here is a sample warehouse layout diagram (not to scale):

Contact us to discuss how we can help you achieve the goals of effective inventory control:

- Operate a safe work environment

- Meet customer delivery expectations

- Protect inventory from breakage, loss, spoilage and theft

- Maintain accurate on-hand quantities

- Store products to minimize the cost of filling orders